최고의 명성을 자랑하는 Buehler사가 에스티키원(주)과 함께합니다.

Abrasive Cutter견적문의

AbrasiMet M Manual Abrasive Cutter

The AbrasiMet M is a benchtop manual cutting machine for 10in [254mm] and 12in [305mm] bladesthat provides consistent sectioning results. The sliding door allows easy access to the cutting chamber to quickly position samples for cutting. A powerful motor and ergonomic cutting arm provide a smooth and efficient cutting motion. The AbrasiMet M is a durable machine that provides users with a quick, clean and simple solution for their cutting needs.

AbrasiMatic 300 Abrasive Cutterr

The AbrasiMatic 300 Abrasive Cutter is a bench top cutter featuring manual cutting action in 3 directions or automated cutting in 1 direction. The 4 sectioning methods available are: Z-axis(up-down) chop direction, X-axis serial section direction, Y-axis longitudinal direction, or automatic Y-axis sectioning.

Delta Manual Action Cutter

The Delta Manual Action Cutter, quickly cuts samples up to 5in [127mm]. An adjustable, manual lever arm enables operators to control the feed rate. Three button control is simple to operate. Highlights: large workspace, accessible blade chaning, coolant spray shield, hood safety lock, electronic brake.

AbrasiMet XL-Pro Automatic Abrasive Cutter

The AbrasiMet™ XL Pro is a floor standing automatic abrasive cutting machine for 14in [356mm] to 18in [457mm] blades that provides consistent and repeatable cut quality for larger diameter samples. An intuitive user interface with programmable methods allows users to create and save multiple sectioning programs for quick access. The machine’s large chamber and powerful motor allow for fast sectioning of large workpieces with ease. The AbrasiMet XL Pro is the ideal machine for use in demanding environments.

Precision Cutter견적문의

IsoMet™ Low Speed Cutter

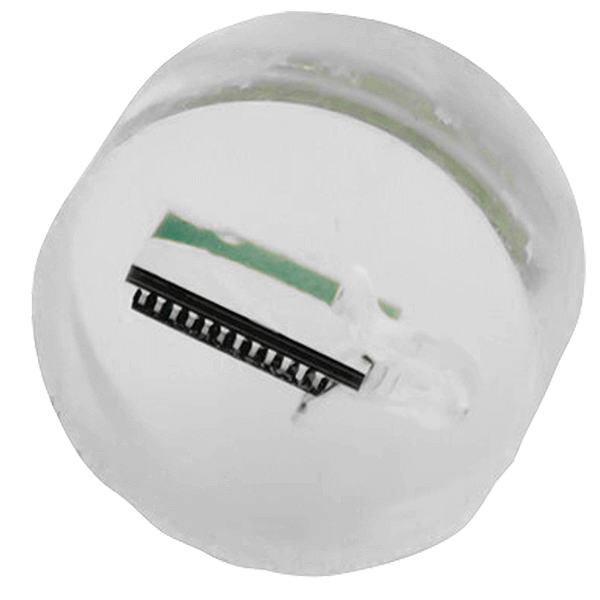

The IsoMet Low Speed Cutter is a precision sectioning saw designed for cutting various types of materials with minimal deformation. Its low kerf loss capability and great versatility in holding all types of sample shapes and configurations, gives today's laboratory a precision sectioning tool capable of cutting viturally any mateiral including brittle or ductile metals, composites, cements, laminates, plastics, electronic devices and biomaterials.

ISOMET 1000 Precision Saw

The IsoMet 1000 is a precision sectioning saw designed for cutting various types of materials with minimal deformation. Its low kerf loss capability and great versatility in holding all types of sample shapes and configurations, gives today's laboratory a precision sectioning tool capable of cutting viturally any material including brittle or ductile metals, composites, cements, laminates, plastics, electronic devices and biomaterials. When equipped with the optional rotating chuck, sectioning times are dramatically reduced.

ProThin Thin Sectioning System

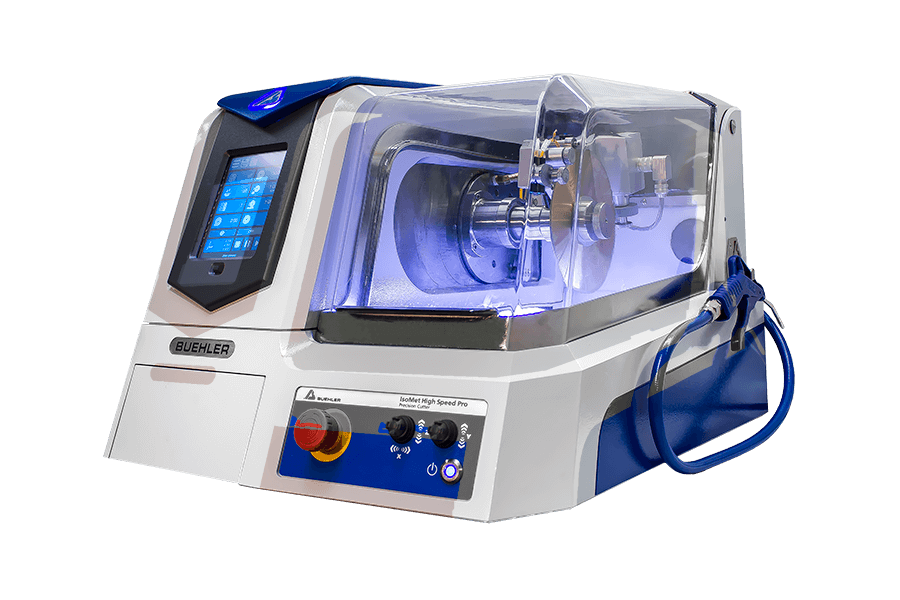

ISOMET High Speed & High Speed Pro

The Buehler IsoMet High Speed Pro is a table top precision saw that provides efficient and precise cuts with intuitive control. The innovative machine and vise designs make setup quick and simple. Align cuts quickly by using the precision laser, tool-less adjusting and the 3-axis blade movement. Precision and abrasive cut samples are now made quicker without impacting cut quality.

The IsoMet High Speed Pro has a blade motor power of 2kW, which is the strongest motor on the market. This motor power ensures the blade will minimize the deformation of the sample surface, saving you time later in the material preparation process. Reduce the cut time without impacting the surface quality.

The IsoMet High Speed Pro has a variety of programmable capabilities. The simple user interface keeps the most important and frequently used features within one touch from the home screen.

ISOMET High Speed

IsoMet High Speed Pro

Compression Mounting견적문의

Simplimet4000

The Fastest Mounting Press Designed for 24/7 Use. Eliminate bottlenecks at the mounting stage, rapidly transforming your cut samples to specimens ready for grinding and polishing. The SimpliMet 4000 mounting press, was tested in extreme conditions, and simulated the duty cycle of the busiest labs in the world, providing high reliability in continuous use environments. The automatic SimpliMet 4000 mounting press packs fast mounting cycles into limited bench space, optimizing productivity. By replacing older, slower, larger mounting presses; capacity can be doubled for the same amount of space. Use your mounting press out of the box without the wait. New employees can be trained quickly and efficiently

Cast N' Vac 1000 Vacuum System

This castable mounting vacuum system for epoxy offer excellent pore impregnation in a compact format. As a result, edge retention is enhanced and friable samples are supported during grinding and polishing. The Cast N’ Vac removes trapped air from mounting material, and fills voids in the specimen. This enhances edge retention and supports delicate and friable samples.

Grinding & Polishing견적문의

AutoMet™ 250 Grinder-Polisher

The AutoMet line of grinder and polisher machines are built for demanding production lab environments. The AutoMet 250 is designed for manual or automated sample preparation. Simplicity is balanced with versatility to accommodate many applications. The AutoMet 250 is built with durable construction for reliability in high use environments, unique quick cleaning features, and plenty of enhancements for user friendly operation.

AutoMet™ 250 Grinder-Polisher Pro

The AutoMet line of grinder and polisher machines are built for demanding production lab environments. The AutoMet 250 Pro is complete with color touchscreen controls and is designed for manual or automated sample preparation. Simplicity is balanced with versatility to accommodate many applications. The AutoMet 250 Pro is built with durable construction for reliability in high use environments, unique quick cleaning features, and plenty of enhancements for user friendly operation. Machine can be equipped with automated dispenser programmability for additional cost savings and highly reproducible results.

AutoMet™ 300 Grinder-Polisher Pro

The AutoMet line of grinder and polisher machines are built for demanding production lab environments. The AutoMet 300 Pro is complete with color touchscreen controls and is designed for manual or automated sample preparation. Simplicity is balanced with versatility to accommodate many applications. The AutoMet 300 Pro is built with durable construction for reliability in high use environments, unique quick cleaning features, and plenty of enhancements for user friendly operation. Machine can be equipped with automated dispenser programmability for additional cost savings and highly reproducible results.

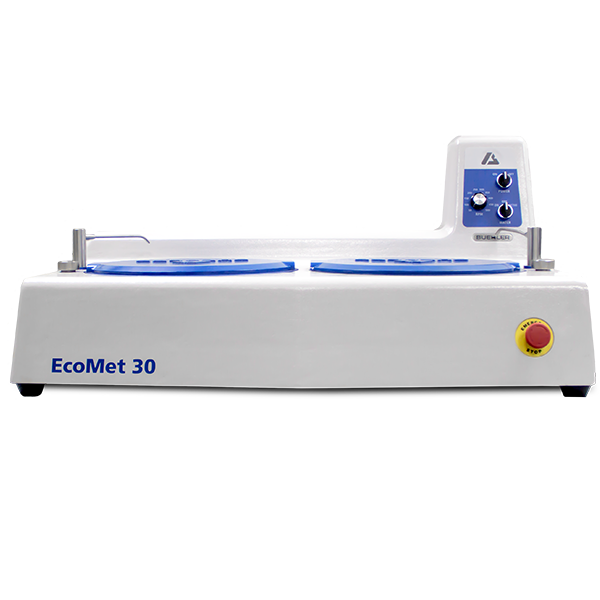

EcoMet™ 30 Manual Grinder Polisher

The EcoMet 30 provides simple operation for manual grinding and polishing. The comfortable splash guard design allows for excellent control while holding a part. Easy to use and easy to clean. Durability tested over 2500 hours and flexible enough to be compatible with 8in [203mm], 10in [254mm] and 12in [305mm] platens

1구형 수동 연마 방식

2구형 수동 연마 방식

EcoMet™ 30 Automatic Grinder Polisher

The EcoMet 30 provides simple operation for routine grinding and polishing. The user-friendly touchscreen interface puts all regularly used functions on the front screen with no complicated menus that can add time to the process. Ideal for users who have a dedicated machine for each step in their process, the EcoMet 30 saves time with advanced cleaning features. Durability tested over 2500 hours and flexible enough to be compatible with 8in [203mm], 10in [254mm] and 12in [305mm] platens. Connect up to 3 Burst Modules for automatic dispensing and increased throughput.

EcoMet Auto Single

EcoMet30 Auto Twin

PlanarMet™ 300 Planar Grinder

The PlanarMet 300 bench top planar grinding machine with a high torque, continuous duty, 5.7Hp motor has an aggressive material removal rate normally seen in much larger, more expensive floor model machines. Convenience features such as an integrated auto wheel dressing, compact interlocking safety cover, and built in cooling make it easy to get consistent results with this planar grinder. The compact bench top design enables the PlanarMet 300 to sit side-by-side with the EcoMet and AutoMet Grinder-Polishers. The PlanarMet 300 uses the same central force specimen holders as EcoMet/AutoMet Grinder-Polishers, allowing additional preparation steps to be completed without transferring to a new holder. Use our planar grinding stones for consistent scratch patterns and high material removal rates.

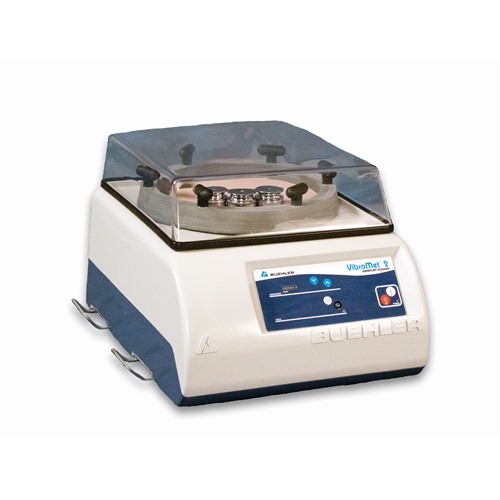

VibroMet 2

진동 연마로 높은 수준의 최종 연마 결과 제공 / EBSD 분석에 탁월 / 12in (305mm) 연마판 사용

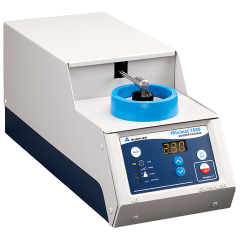

MiniMet™ 1000

The MiniMet 1000 semi-automatic grinder/polisher is a low volume, single specimen machine capable of preparing a wide variety of materials. The MiniMet 1000 prepares a wide variety of materials using the three self-contained preparation bowls and easy-touch panel controls. This semiautomatic grinder-polisher uses space saving design employs geometric action, increasing specimen consistency.

ElectroMet 4

The ElectroMet 4 is an electropolishing and etching system with interchangeable cathodes and etching cell. Electrolytic sample preparation provides an efficient method for final polishing and etching of metal alloys including stainless steel, aluminum, titanium, copper and many more. The ElectroMet 4 electro-polisher/ etcher is designed for optimal performance and ease of operation. It consists of a power source, a polishing cell, an etching cell, a specimen stand, and other accessories.

Consumables견적문의

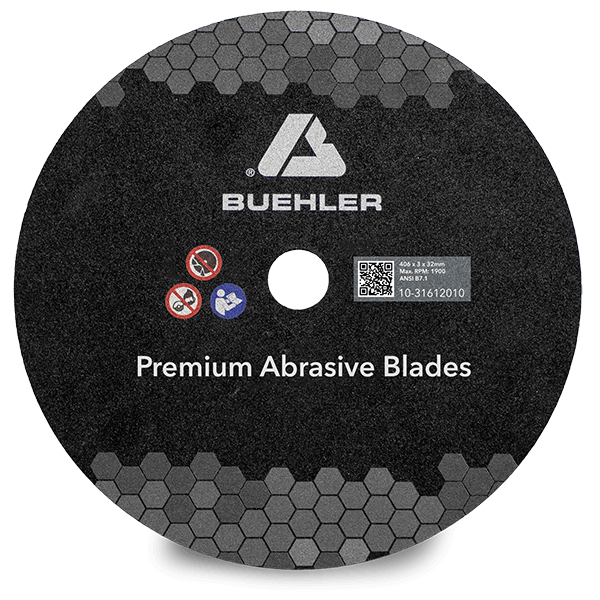

Abrasive Blades

Abrasive cutting is the most common method of sectioning to achieve a clean and efficient cut. Buehler's abrasive blades are designed to provide high quality sectioning results with no burning and minimal surface deformation.

Buehler carries a wide range of different metallographic abrasive blades for sectioning machines that can be used for many different applications. Our abrasive blades have diameter ranges from 5 in (127 mm) to 18 in (455 mm), arbor sizes ranging from 0.5 in (12.7 mm) to 1.25 in (31.75 mm), blade thicknesses ranging from 0.0020 in (0.5 mm) to 0.063 in (1.6 mm) and dimensions ranging from 5.9 in (150 mm) to 9 in (230 mm).

Our abrasive blades are frequently used for sectioning many different materials including but not limited to ferrous materials, soft, medium, hard, and tool steel, stainless steel, super alloys, titanium alloys, and zirconium alloys.

Abrasive Vises For Sectioning

Vising is a critical component to efficient sectioning. Buehler's abrasive vise offering for abrasive cutting machines provides reliable and versatile clamping options that ensure the sample is secure and properly presented for sectioning.

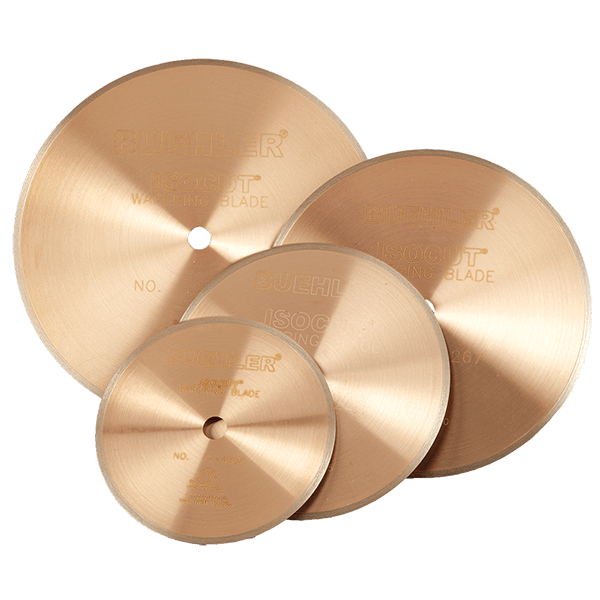

Diamond and CBN Blades

Diamond blades and CBN (Cubic Boron Nitride) cutting blades are the preferred blade type when delicate and precise sectioning is needed. Diamond and CBN blades also perform better than traditional abrasive blades when cutting certain materials, especially very hard materials.

Buehler carries many different CBN blades and diamond blades in various diameters and thicknesses for many materials and applications including general use, hard materials, ceramic and petrographic samples, plastics and polymers, steel, and many more. Refer to the Ordering chart below to find the ideal diamond blade or CBN blade for your material and end application.

Sectioning Coolants

Proper cooling is critical to the sectioning process of metallographic sample preparation. Buehler's line of cutting fluid coolants are designed to dissipate heat and remove swarf from the cutting point. Cutting coolant fluid helps to dissipate heat and remove swarf from the cutting point. This enables the abrasive, diamond, or CBN blade to achieve maximum cutting efficiency and prevent any unnecessary surface damage to the sample.

Our cutting fluid coolants and lubricants include water miscible and oil based coolants. We also carry cleaning agents, additives for coolants to prevent corrosion, and clear pastes for cutter windows to improve visibility.

Refer to the specifications and ordering information below to find the right coolant for your sectioning application.

Precision Vises

Often times, the samples being cut are not standard shapes and a unique clamping solution is required. Buehler's precision vises offer solutions for varying shapes and sizes to allow for precise and consistent cut locations.

Buehler has many different types of precision vises for various applications including slotted vises, sliding vises, single and double saddle chucks, glass slide chucks, mount chucks, wafer chucks, and more.

Refer to the Ordering tab below to find the ideal precision vise for your sectioning application.

Flange Sets

Flange sets support Diamond, CBN, and abrasive blades when using the IsoMet saw line. Choose the best diameter size flange depending on the size and type of material.

Our precision cutter flange sets support Diamond and CBN blades for best cut. Buehler carries aluminum flange sets and stainless steel flange sets of varying diameters. Find the ideal flange set for your application by using the Ordering section below.

Compression Mounting Powder & Pre-Molds

Compression mounting compounds utilize heat and pressure to encapsulate a specimen. Buehler's compression mounting media includes resins, phenolic powder, compression mounting powder and pre-molds that minimize shrinkage while protecting and preserving sample edges during the preparation process.

The choice of a compression mounting media compound depends on the goals of the lab and requirements of final analysis. Many different powders and pre-molds are available to meet the wide variety of needs including colored general purpose phenolic powder, hard mineral filled compounds, clear thermoplastic compounds and conductive compounds for SEM analysis.

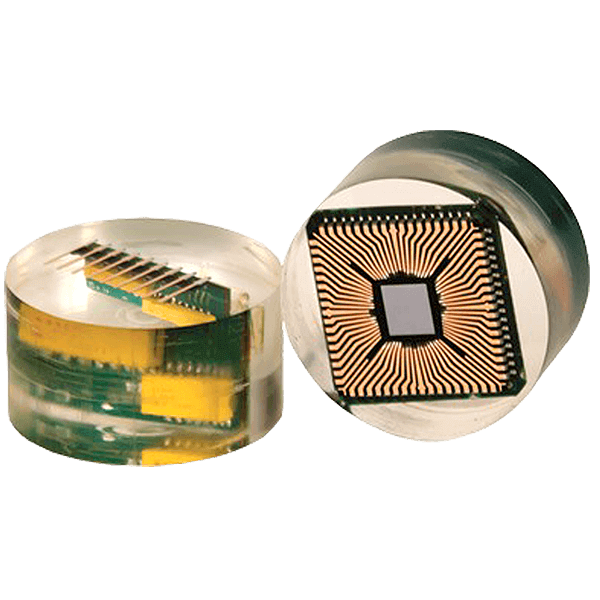

Acrylic Mounting Systems

Acrylic mounting systems offer a short cure time and are recommended for mounting specimens that are sensitive to high pressures and temperatures. Buehler's offering includes acrylic liquid, powder and kits designed for different metallographic sample testing applications.

SamplKwick - acrylic mounting compound is designed for rapid and effective encapsulation of PCB coupons. By dipping coupon in Acrylic liquid prior to potting, Buehler’s SamplKwick is able to wet and enter into smaller holes and recesses well, with ease offering good penetration and the edge retention needed for great electronics preparation. To reduce the viscosity of mixed acrylic, powder to liquid volume mixing ratio of 1:1 or 1.5:1 is preferable.

VariKleer - is ideally designed to use with pressure vessel to generate crystal clear acrylic mount resulting harden and minimum shrinkage, to determine the PCB coupon sample grinding to desire level. For crystal clear mount, SamplKup should be used rather than EPDM or Disposable mount.

VariDur - is a fast acrylic system containing filler resulted in harden mount particluarly for metals sample in short curing cycle with compare to epoxies and when edge retension is not critical.

Epoxy Mounting Systems

Epoxy mounting resin and hardener systems are recommended for mounting specimens that are sensitive to high pressures and temperatures. Buehler's epoxy resin and hardener products provide good physical adherence, low shrinkage, and excellent infiltration into pores.

Epoxy chemistry is a complex balance of many factors including shrinkage, cure time, viscosity and adherence. Each lab application requires a slightly different priority of these factors and our line of epoxy mounting resins and hardeners has been specially developed to provide the ideal product for your application.

Some applications require the performance of epoxies but demand a quick cure time. EpoKwick FC and EpoHeat CLR resins and hardeners are the ideal products for these applications.

Mount & Mold Release Agents

Release Agents help prevent mounts from sticking to the mold chamber or mounting cups during compression or castable mounting. Buehler offers multiple different mold release agent products to meet your application.

Mounting Accessories

Many different specimen support clips, mounting cups, pigments and fillers are available to help simplify, improve, or customize a mounting process for metallographic sample preparation.

Planar Grinding Stones

Buehler’s Planar grinding stones are multi-use abrasive discs designed for the PlanarMet 300 planar grinding machine. They provide high material removal rates and consistent scratch patterns.

Aluminum Oxide Grinding Stone

Versatile abrasive recommended for both hard and soft materials and for extended wheel life. For grinding or cutting carbon steel, high speed steel, tool and die steel and other high alloy, high tensile strength materials.Silicon Carbide Grinding Stone

A very hard, sharp abrasive grain. Used in grinding of cast iron, aluminum, copper, bronze and non-metallic materials such as plastic and glass. Find all planar grinding stone options in the Ordering tab below.

Silicon Carbide Grinding Papers

Buehler’s CarbiMet & MicroCut Silicon Carbide grinding papers are the premier line of SiC grinding discs offering efficient material removal and minimal surface damage. Our discs come in various grit sizes, micron sizes and diameters.

CarbiMet Silicon Carbide grinding discs offers quick grinding times with minimal surface damage during the grinding process. Since there is less damage to remove, the amount of subsequent processing may possibly be reduced, saving valuable time the preparation process.

Apex S Backing allows for fast changeovers between CarbiMet steps. Simply remove the previous SiC grinding paper and apply the next one without needing to remove any backings or liners.

MicroCut abrasive papers provide gentle material removal and superior surface finish when processing delicate or sensitive materials.

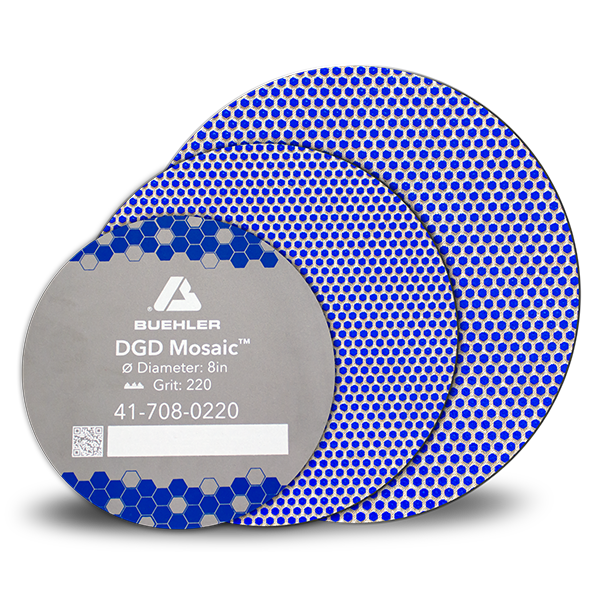

Diamond Grinding Discs

Diamond grinding discs offer a long-wear surface that provides excellent surface flatness for a wide variety of materials. Fixed diamond particles in Buehler's diamond grinding discs provide consistent removal rates and extended lifetime with only an occasional dressing to maintain the surface. The combination of great edge retention, long lifetime, and consistency makes Buehler’s diamond grinding discs the perfect choice for controlled material removal on automated systems.

Buehler offers multiple different types of diamond grinding disc products depending on the material being processed as well as the speed and surface quality needed.

CGD provides: Very high removal rate with excellent flatness designed for materials not susceptible to excessive damage; excellent for high strength materials and stock removal.

DGD Mosaic provides: high material removal rate with good surface quality and great flatness; excellent for strong materials and stock removal.

DGD Ultra provides: relatively high removal rate with good surface quality; great for initial grinding steps for samples with mixed hardness materials.

DGD Color provides: good removal rate with great surface quality, flatness, and consistency; great for a wide range of materials especially softer metals.

DGD Terra provides: very gentle removal rate with excellent flatness and surface quality; excellent for brittle and delicate materials (e.g. ceramics, glass) .

Polishing Cloths

Polishing cloths for metallographic sample testing are used along with an abrasive to remove layers of surface deformation and expose the material structure for analysis. Because polishing is such a critical step in sample preparation, it’s important to choose a high quality polishing cloth. Buehler's metallographic polishing cloth pads are thoroughly tested and developed with MetaDi Diamond to provide a complete solution that delivers reliable results for each sample processed. The type of polishing cloth used depends heavily on the material being processed and the requirements for the final analysis. With a variety of fabrics, weaves and naps, Buehler has a cloth to fit every application. Polishing cloths are available with PSA and Magnetic backings. Utilize the magnetic backing for an efficient and easy-to-use solution. The durable magnet provides consistent polishing results while reducing the changeover time between cloths. See the Buehler Polishing Guide for more information, tips, and selection guide.

Diamond Suspensions and Paste

MetaDi diamond suspensions and pastes are high-quality monocrystalline and polycrystalline diamond polishing products that provide repeatable performance and deliver exceptional sample quality.

Buehler's MetaDi diamond suspension polishing and paste products are tightly controlled to prevent any deviations in particle size or concentrations. This ensures reproducible polishing results and a high quality surface finish for every sample processed.

Color coded diamond suspensions and pastes based on the micron size helps prevent cross contamination on polishing surfaces.

Some materials are not compatible with traditional water-based suspensions due to water-sensitivity or diamond embedding. The Oil-Based MetaDi Monocrystalline diamond suspension as well as MetaDi diamond pastes offer multiple options when working with water-sensitive materials.

Final Polishing Suspensions

Final polishing suspensions are designed to remove the final layer of surface deformation and prepare a sample for analysis. Deformities may not be visible to the naked eye, but must be removed for some specimen analysis techniques.

A variety of alumina and silica products are offered by Buehler including colloidal silica polishing suspension to meet many different application needs.

Refer to the Ordering tab below to find the right final polishing suspension or powder for your application.

Specialty Grinding & Polishing

Some applications can benefit from a specialty product or solution. Unique holders are available for processing circuit boards along with a variety of abrasive lapping discs and powders.

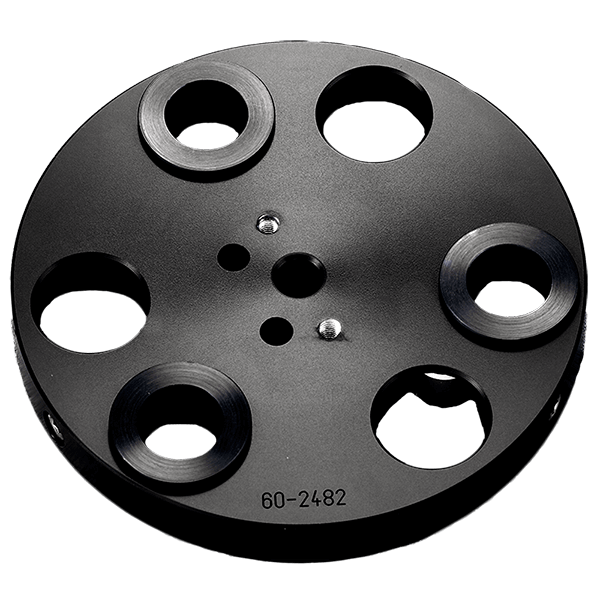

Sample Holders

Sample holders are designed for use with Buehler's grinder-polishers to facilitate process automation and optimization. Many options for different sample sizes and shapes are available depending on the shapes, sizes, and capacities required.

Platen Systems

Many different magnetic platen systems for sample preparation are available to facilitate the use of different grinding & polishing surfaces on Buehler's grinder-polishers.

Specialized, high friction surface allows for fast application and removal of surfaces during the preparation process. The base of the platen system is an aluminum platen with an Apex S film.

CarbiMet S and MicroCut S products are designed for use with this magnetic platen system.

Versatile Magnetic Platen System: The magnetic system offers quick changing of surfaces with a variety of surfaces to choose from. The base of the system is an aluminum platen with a magnet attached. Many diamond grinding discs and polishing cloths (link to each consumables page) are available with a magnetic backing to affix directly to the magnetic platen. Magnetic carrier plates are also available for use with PSA backed products.

Replicating Media

Field metallographic replication is required in some applications where it is not possible to remove a component from service, or the size prohibits analysis in the lab. Replicating Media allows users to create a portable copy of the microstructure of interest.

Replicating Media for metallographic replication is a two-part silicon system that is simple to use, provides excellent dimensional stability, and has a relatively quick cure time. Metallographic replicating tape, or 'Acetate', is a thin film that provides excellent spatial resolution but demands extra care.

Both Replicating Media and Replicating Tape for metallographic field use create a 3D surface replica for analysis and examination.

Burst Dispensing System

The Burst Dispensing System is a flexible, easy to operate dispensing system for all diamond and final polishing suspensions. With a variety of operating modes, solutions can be tailored for any Buehler grinder-polisher set-up. This system improves both productivity and consistency by dispensing suspensions at fixed intervals and configurable rates.